At HYT, Quality Is Our Prime Priority

Each and every machine we deliver is checked and tested according to rigorous quality standards to ensure that only the best product reaches the customers. Our products are compliant to latest quality and design standards and are well known for their performance and reliability.

Starting from inspection of raw material to inspection of the final product, different quality checks are applied at each stage during process of verification by our qualified engineers.

The Quality Assurance Plan (QAP) presents a framework for activities, which when followed, will ensure delivery of quality products and services. It is a critical part of any project, as it enables to agree to a set of quality targets. It explains Material control procedure, Acceptance norms, In-process control, Bought out Items Control, Final Inspection Norms, etc.

To help our customers we have established an elaborate after sales and service setup so that services are rendered to the customer on real time basis. A remote diagnostic and assistance facility has also been created has also been created.

Welding facilities

At HYT, We have state of art welding facilities and supporting welding quality systems aimed for excellence. Our systems adhere to strict quality requirements of various international standards of welding like ISO 3834, ASME, AWS, Indian Standards and so on.

We have specialized skills for welding processes GMAW, SMAW, GTAW. Our welding personnel are qualified as per ASME SEC-IX and ISO 9606. The welding procedures are qualified as per ASME Section IX, ISO 15609, ISO 15614 etc. At HYT, we weld carbon steels, high Strength steels, Stainless steels, alloy steels and have capability to expand into more exotic materials.

We have a specialized NDT team and in house NDT equipment for our being self sufficient before customer and Third Party Inspections. We have at our disposal IWE and ISO 9712 qualified consultants with relevant industrial experience.

Thus, HYT competes and strives to be one of the most preferred suppliers of indigenious railway wheel lathes.

We are an ISO 9001:2015 certified company with CE certified Machines.

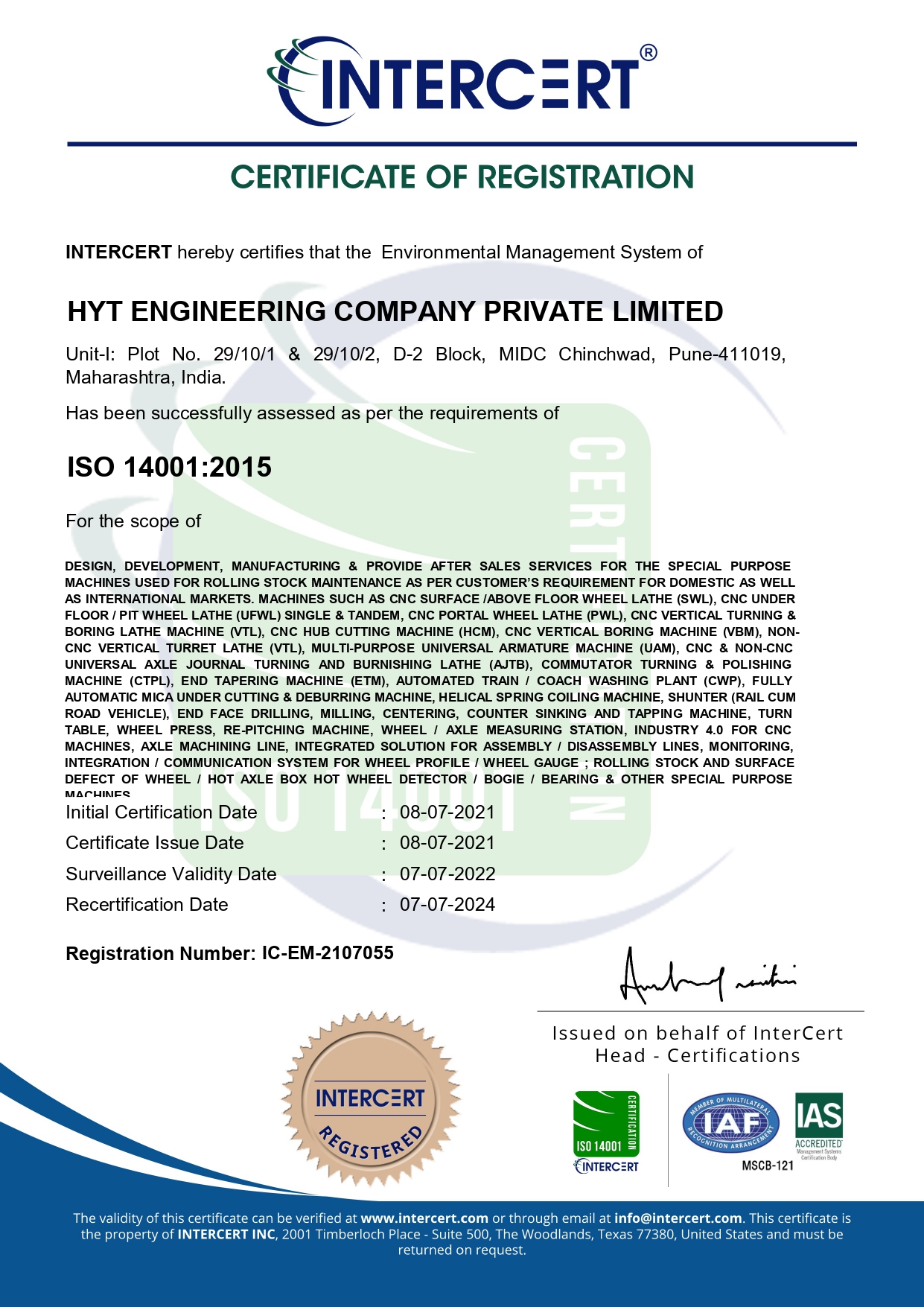

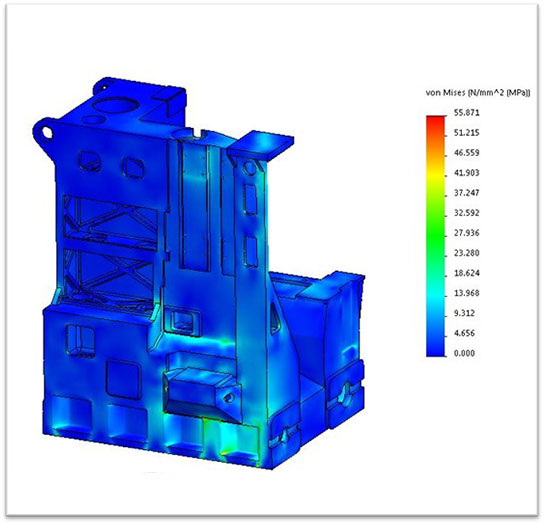

FEM Analysis

During FEA analysis, machine elements are subjected to the intended loads with fixity as per assembly requirements. Stresses induced in the elements together with deflection under load are the results produced by the software. Necessary iterations if necessary are done to maintain induced stress level and deflection levels within acceptable limits as per selected material and accuracy requirements of the machine. This results in machine elements and the complete machine will perform as per required accuracies and will ensure durable performance without premature failure.

Plot No. 29/10, 29/10/1, 29/10/2, D-II Block, MIDC, Chinchwad

Pune – 411019, India

Email us :

info@hytwheellathes.com

Call us :

+91 20 66343900 / 06