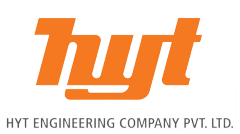

CNC Surface Wheel Lathe

YSL-08

Technical Data of Machine

| Max. Main Drive Motor Capacity | 2 x 45 or 55 KW |

| Cutting Speed while Profiling | 25 to 80 m/min |

| Tool Post Feed for Wheel Profiling | 0.1 to 3.5 mm/rev |

| Tool Post Rapid Speed for Both Axes | 3000 mm/min |

| Max. Chip Cross Section while Profiling | 20 mm2 |

| Cycle Time / Wheel Set | 14-16 min. |

Wheel Set Data for Machining

| Max. Tread Diameter | 1250mm* |

| Min. Tread Diameter | 750mm* |

| Wheel Width | 75 to 145mm |

| Max. Axle Length | 2750mm* |

| Min. Axle Length | 1200mm* |

| Max. Weight of Wheel Set | 50 kN |

| Max./Min. Dia. for Brake Disc Machining | 700/250mm |

*Depends on track gauge

Accuracies of Wheel Set

| Wheel Profiling | |

| Max. Difference in Dia. of Both Wheels | <0.15mm |

| Accuracy of Wheel Profile when Compared with Standard Gauge | <0.2mm |

| Radial Run Out of Wheel | <0.2mm |

| Axial Run Out of Wheel | <0.2mm |

| Profile Surface Finish | <12.5µm Ra |

| Brake Disc Machining (Optional) | |

| Min. Surface Finish | <2.5µm Ra |

| Flatness of Surface | <0.1/100mm |

| Lateral Wobble | <0.2mm |

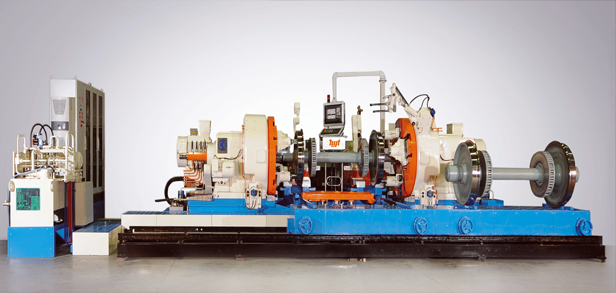

YSL-12

Technical Data of Machine

| Max. Main Drive Motor Capacity | 2 x 37.5 KW |

| Cutting Speed while Profiling | 25 to 80 m/min |

| Tool Post Feed for Wheel Profiling | 0.1 to 3.5 mm/rev |

| Tool Post Rapid Speed for Both Axes | 3000 mm/min |

| Max. Chip Cross Section while Profiling | 16 mm2 |

| Cycle Time / Wheel Set | 16-18 min. |

Wheel Set Data for Machining

| Max. Tread Diameter | 1250mm* |

| Min. Tread Diameter | 750 mm* |

| Wheel Width | 75 to 145mm |

| Max. Axle Length | 2750mm* |

| Min. Axle Length | 1200mm* |

| Max. Weight of Wheel Set | 50 kN |

| Max./Min. Dia. for Brake Disc Machining | 700/250mm |

*Depends on track gauge

Accuracies of Wheel Set

| Wheel Profiling | |

| Max. Difference in Dia. of Both Wheels | <0.3mm |

| Accuracy of Wheel Profile when Compared with Standard Gauge | <0.2mm |

| Radial Run Out of Wheel | <0.3mm |

| Axial Run Out of Wheel | <0.3mm |

| Profile Surface Finish | <12.5µm Ra |

| Brake Disc Machining (Optional) | |

| Min. Surface Finish | <2.5µm Ra |

| Flatness of Surface | <0.1/100mm |

| Lateral Wobble | <0.3mm |

YSL-21

Technical Data of Machine

| Max. Main Drive Motor Capacity | 1 x 22 KW |

| Cutting Speed while Profiling | 25 to 80 m/min |

| Tool Post Feed for Wheel Profiling | 0.1 to 3.5 mm/rev |

| Tool Post Rapid Speed for Both Axes | 3000 mm/min |

| Max. Chip Cross Section while Profiling | 10 mm2 |

| Cycle Time / Wheel Set | 50-60 min. |

Wheel Set Data for Machining

| Max. Tread Diameter | 1250mm* |

| Min. Tread Diameter | 750mm* |

| Wheel Width | 75 to 145mm |

| Max. Axle Length | 2750mm* |

| Min. Axle Length | 1200mm* |

| Max. Weight of Wheel Set | 50 kN |

| Max./Min. Dia. for Brake Disc Machining | 700/250mm |

*Depends on track gauge

Accuracies of Wheel Set

| Wheel Profiling | |

| Max. Difference in Dia. of Both Wheels | <0.5mm |

| Accuracy of Wheel Profile when Compared with Standard Gauge | <0.3mm |

| Radial Run Out of Wheel | <0.3mm |

| Axial Run Out of Wheel | <0.3mm |

| Profile Surface Finish | <12.5µm Ra |

Max./Min. Dia. for Brake Disc Machining on all products and all products pages.

CNC Surface Wheel Lathe is an automatic machine for simultaneous re-profiling new or worn-out wheels when disassembled from railway vehicles like locomotives, electrical and diesel multiple units, coaches, wagons, metro & tram coaches.

Pl. note that improvements is a continuous process. Hence, details explained above may undergo some changes meeting functional, quality and productivity requirements of the required technical specification.

Why you choose us for your next project!

- Automatic roll-in and roll-out of wheel set through travers to increase productivity.

- All load-bearing structures subjected to cutting loads are built with high strength, close-grained cast iron castings resulting in dimensional & geometrical stability as well as efficient vibration damping.

- CNC based wear measurement system for economical depth of cut.

- Remote Diagnostic software for faster maintenance support from HYT headquarter.

Play Video